Our Services

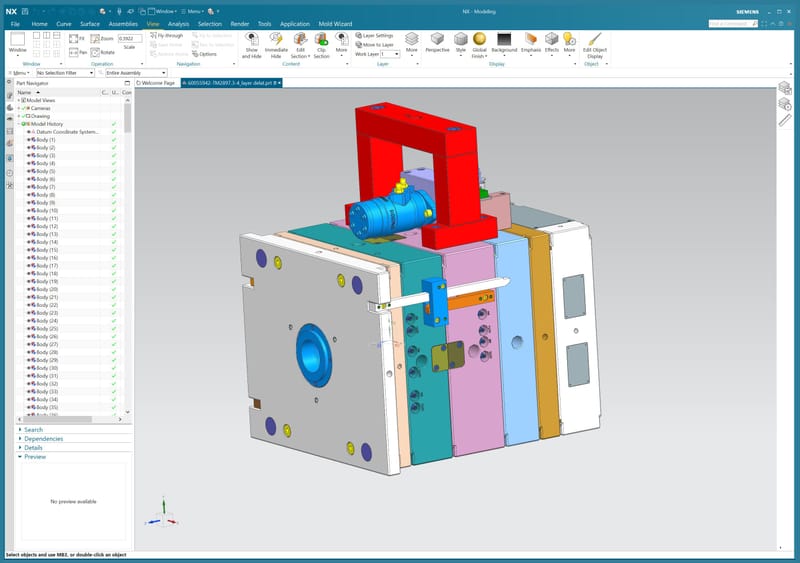

Construction and design

We have Siemens NX CAD and Master CAM software.

3D Printing

Our 3D Printer can print technical plastics. With its double nozzles, it is ideal for printing large high-performance functional materials, e.g. ABS, NYLON, PC, PPSU, ULTEM and PEEK. Its high-temperature thermal system includes a constant chamber temperature of 300°C, with a build volume of 610 x 508 x 508 mm.

Read more about the materials we use

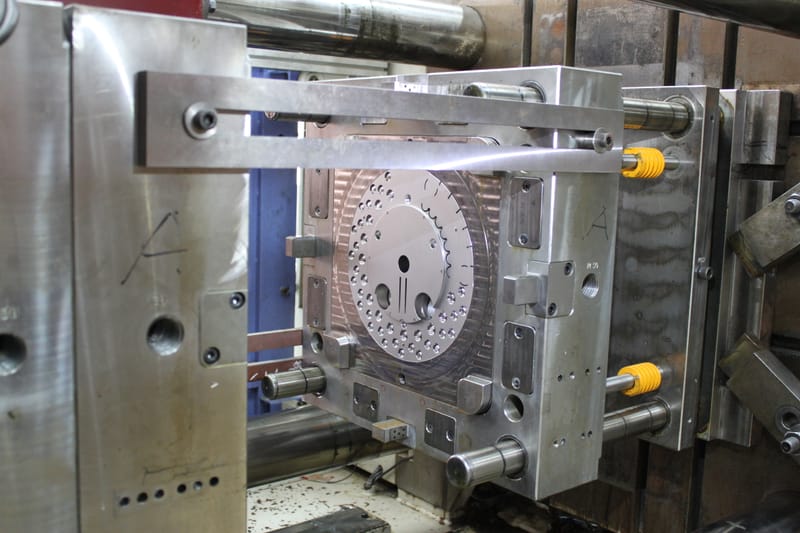

Injection molding

Injection molding is an efficient method for producing high-quality plastic components in large volumes. This enables companies to quickly scale up their production and lower costs, while maintaining strict quality standards. Our service is adapted to meet the specific needs of different industries, medicine and consumer products. Our machinery consists of injection molding machines with clamping force from 25 tons to 250 tons, which means that we can have a large variation in the sizes of the products. We injection mold both volume plastics and technical plastics.

Cutting processing of plastic and metal

We have CNC milling machines with up to 5 axes and CNC lathes to shape and create specific products or components by cutting or removing material from a raw surface. This process may include the use of tools such as milling or drilling to achieve the desired shape or dimension of the material. It is an important method in the manufacturing industry and is used to create everything from small details to larger structures of both plastic and metal.

Spark machining

We undertake sinking and wire sparking assignments. This machining method is used to machine materials that are difficult to cut with traditional methods or when high precision and surface quality are required. This means that we specialize in using electric sparks to process materials and create desired shapes or threads.

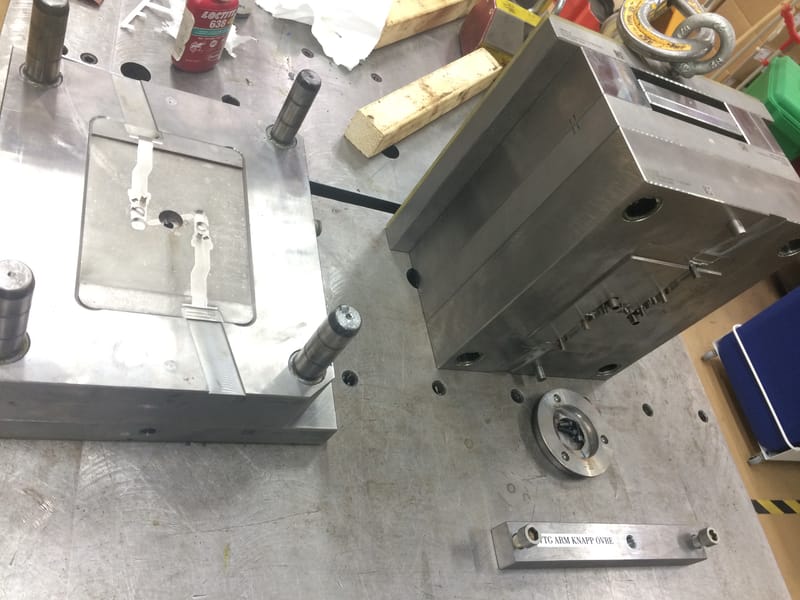

Forming tool

We have our own production of molding tools for plastic injection molding. Forming tools are specialized tools used to shape or manipulate materials, usually in manufacturing or machining processes. These tools can be cast or cut to create the desired shape or pattern on a material. By using molding tools, products or parts can be created with high precision and detail.

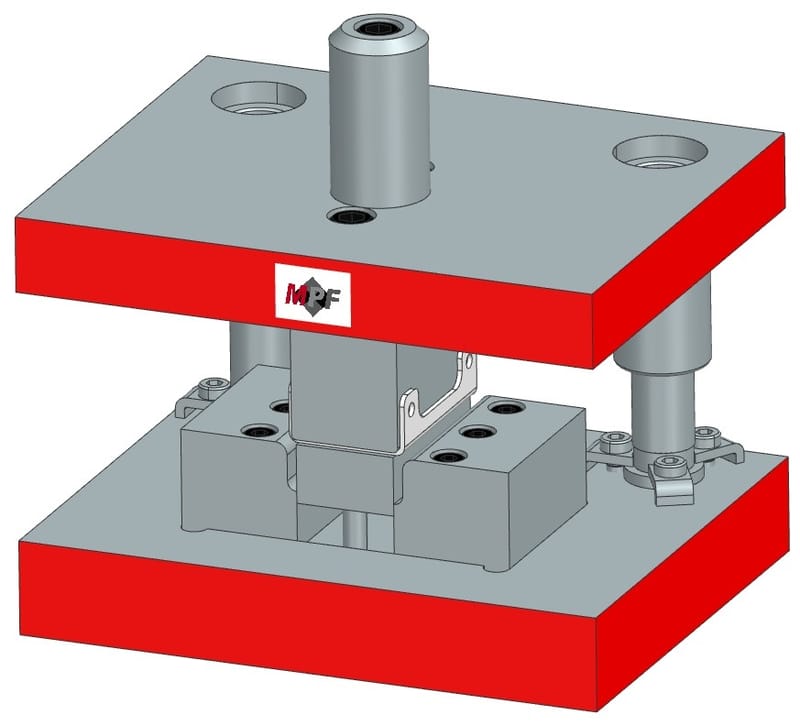

Pressverktyg

Vi konstruerar och tillverkar stans- och bockverktyg för kortserie- och prototyp detaljer. Även tillverkning av komponenter och reservdelar till stans- och bockverktyg. Pressverktyg är ett verktyg som används för att applicera tryck på material för att skapa specifika former. Det kan användas för att bearbeta metaller eller andra material genom att pressa, stansa, böja eller forma dem.

3D Scanning

Our 3D Scanner has an accuracy under laser scanning mode of up to 0.02mm with the ability to select smaller scan areas. This allows one to take advantage of parallel laser scanning lines that provide precise and fine detail scanning of selected lots.

Measuring machine

Our Measuring Machine is an advanced device designed to perform high-precision measurements. It combines robust technology with sophisticated software to guarantee accurate real-time results, making it ideal for quality control and production adjustment.

Laser marking

Our Laser Marking offers a high-quality and non-contact method for marking products or components with identification, logos or technical information. With its extremely fine precision, laser marking guarantees that the marking will be clear and permanent even on small or complicated surface structures.

Surface grinding

We grind metal to achieve perfect flatness and optimal surface properties that improve both appearance and function.

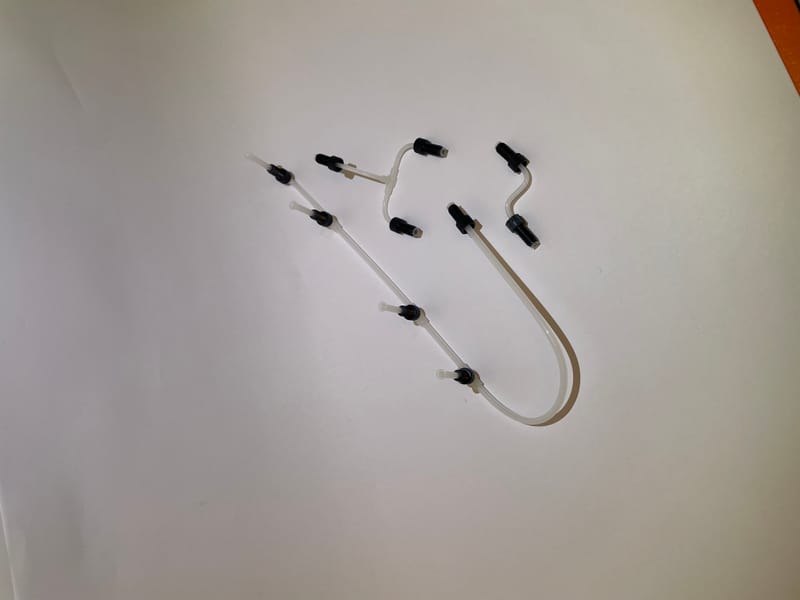

Hose manufacturing

We collar and weld special hose. Collaring plastic is a type of fastener or connection used to connect different pieces of plastic material. It acts as a collar or wreath that holds the plastic parts together in a safe and durable way. Welding specialty hose involves joining parts of a hose in a permanent way through the use of heat, joining or pressing. By welding special hose, you can create tailor-made or specially adapted hoses that meet specific requirements or needs.

Mounting

We carry out complete or partial assembly of articles. It can be done by various methods such as gluing, welding, screwing or using collars or clips. Assembling plastic requires knowledge of the properties of plastic materials and which method is suitable for creating a strong and durable connection. It requires accuracy, precision and quality control to ensure that the products are of a high standard and function correctly.